Valves / Hygienic / Aseptic / Speciality Process Valves

Radial Diaphragm Valve

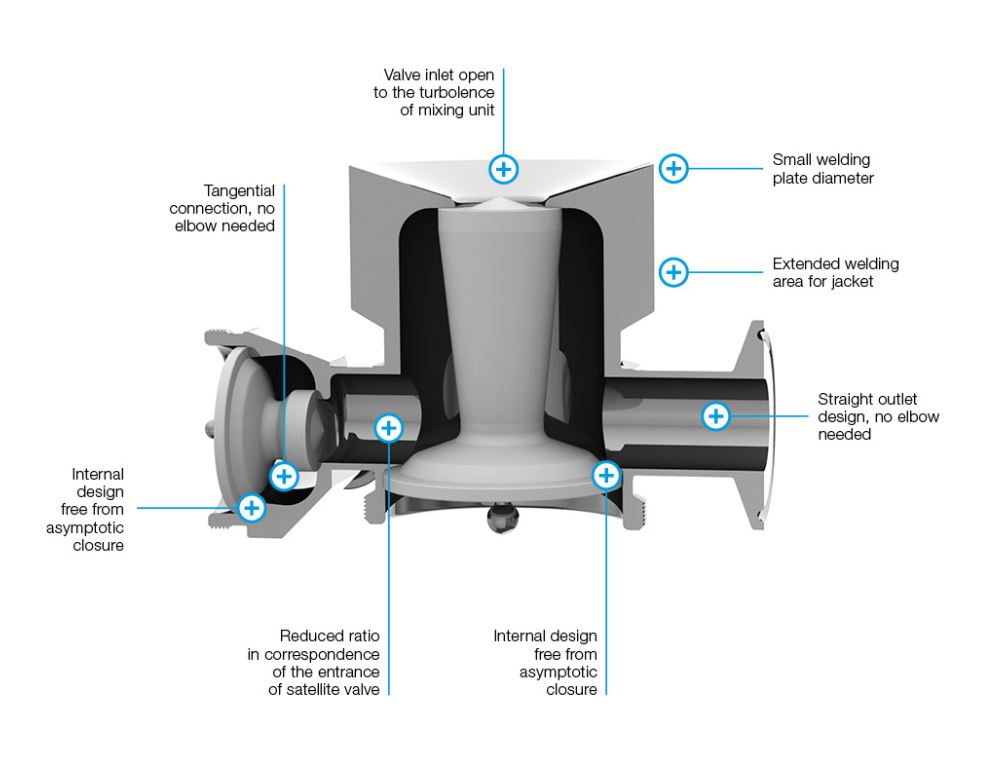

True aseptic valve technology for easy to clean, zero-dead leg, hygienic process systems.

Valves range design

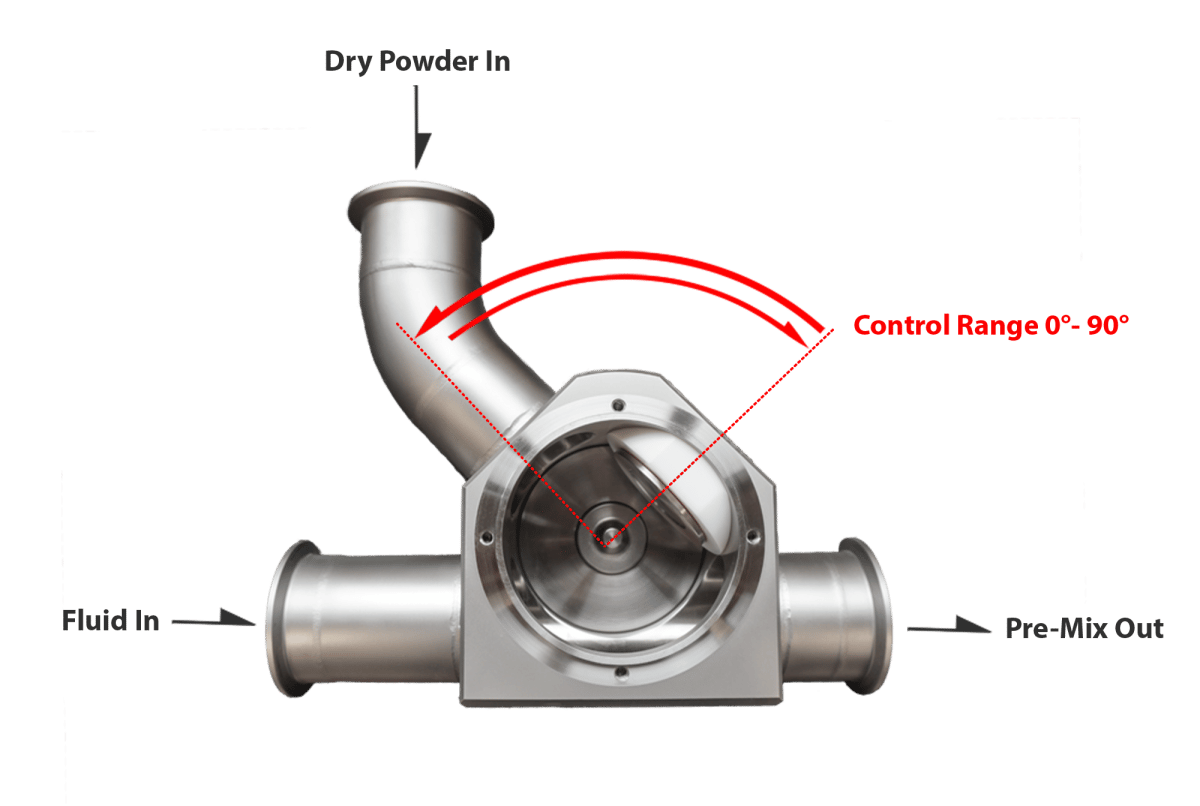

Ratti inox CAD family valves are very wide and under are shown some configurations. Our specialist in process design will support you for choosing the appropriate one or, to help you to design your solution preparation system with the best solution to achieve free unused portion piping, zero dead legs design, minimize solution holds up, compact design with fast and effective CIP and SIP cycles.

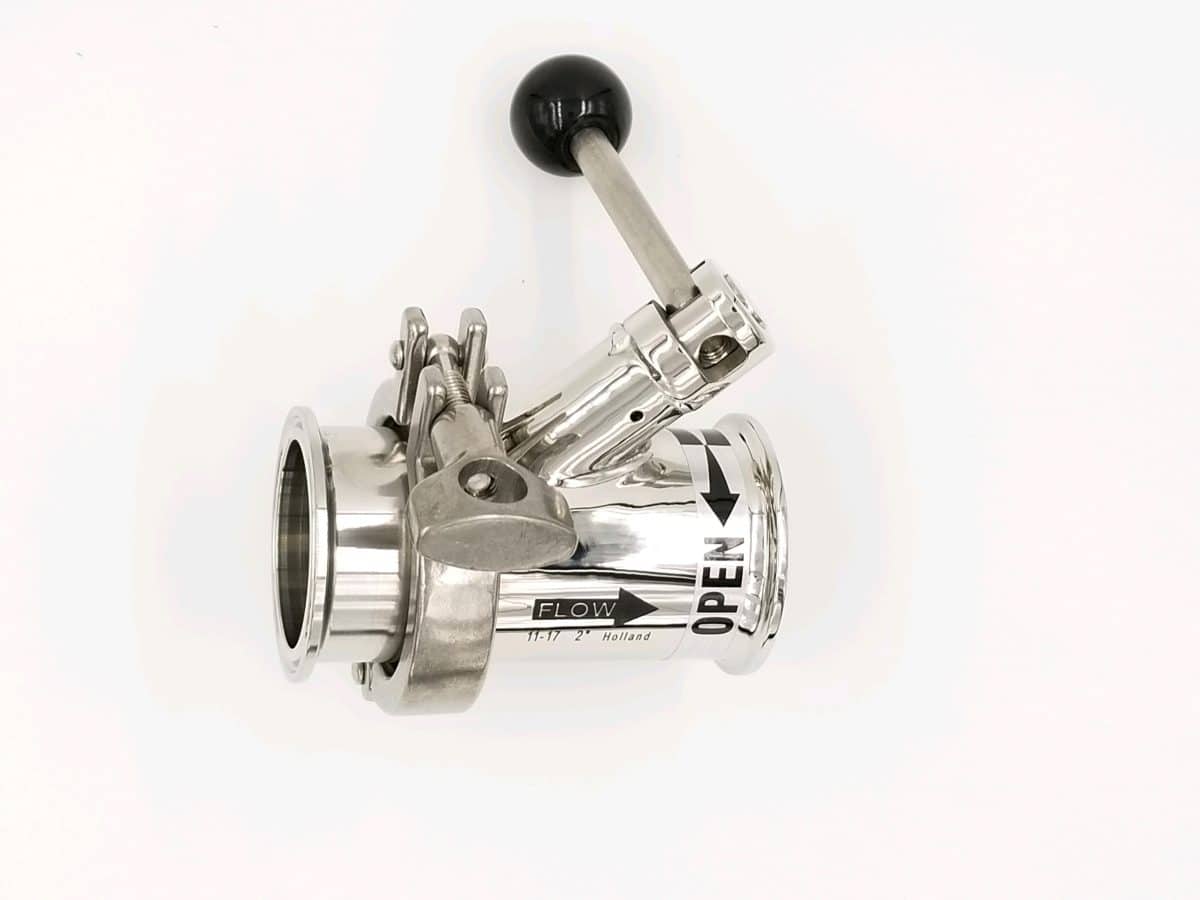

Standard Preassembled Valves

A various valves assembly is available to speed up process constructions. Point of use, bottom point, and others are available as standard products.

Tailored Valves and Valves Assembly

If required, our specialists will be able to design, built and provide with fast delivery special valves or assembly.

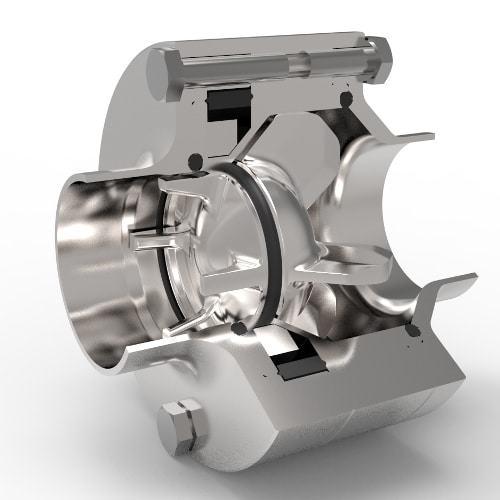

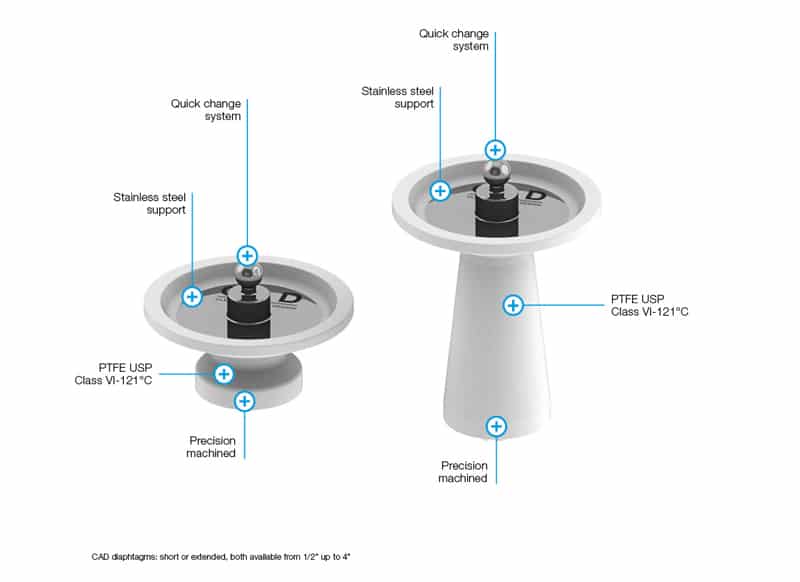

Aseptic processing ask for equipment able to fulfil stringent requirements of CIP and SIP. CAD valves are designed to answer properly process configuration upstream, around and downstream process vessels. The family of CAD valves, also available on ready to use assembly and will offer a wide solution applications able to reach compact design, free of dead legs, allowing to minimize solution hold up. Processing with CAD valves, which are constructed of 2 materials only: EN 1.4435-BN2 and PTFE USP Class VI-121°, will provide you an efficient process system, simple, reliable, and easy to validate.

Complaining CIP-SIP Cycles

No unused portions

Full cleanability and drainability

Design compact

No asymptotic joint

Long diaphragm life

Wide range answering applications needs

Extensive tech documentation for Validation

Built with only 2 materials: SS316L Low Ferrite and PTFE USP Class VI-121°

Meet your clean and aseptic

process specialist

Discover our custom-made solutions and modular sanitary equipment. We join forces with our expert partners to develop, design and integrate proven solutions.