Valves / Hygienic / Aseptic / Speciality Process Valves

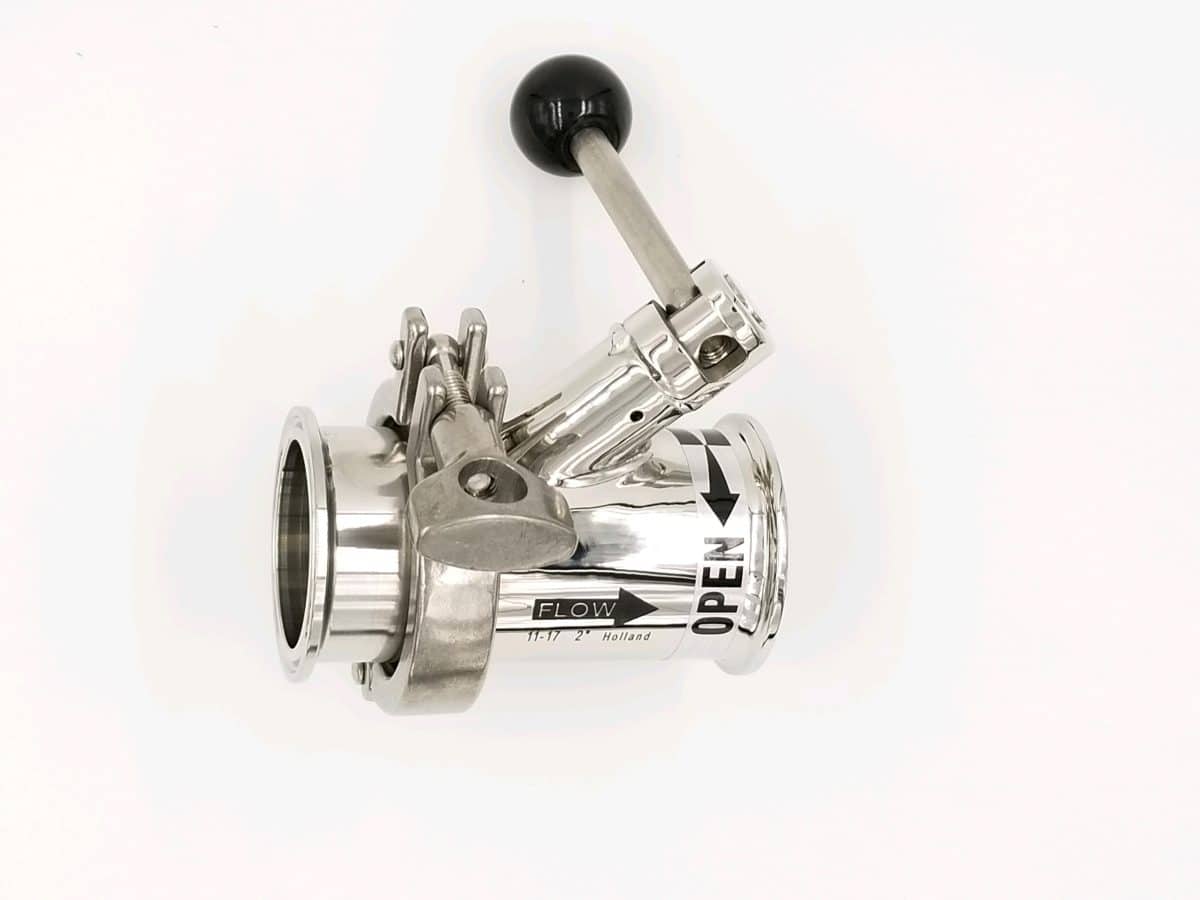

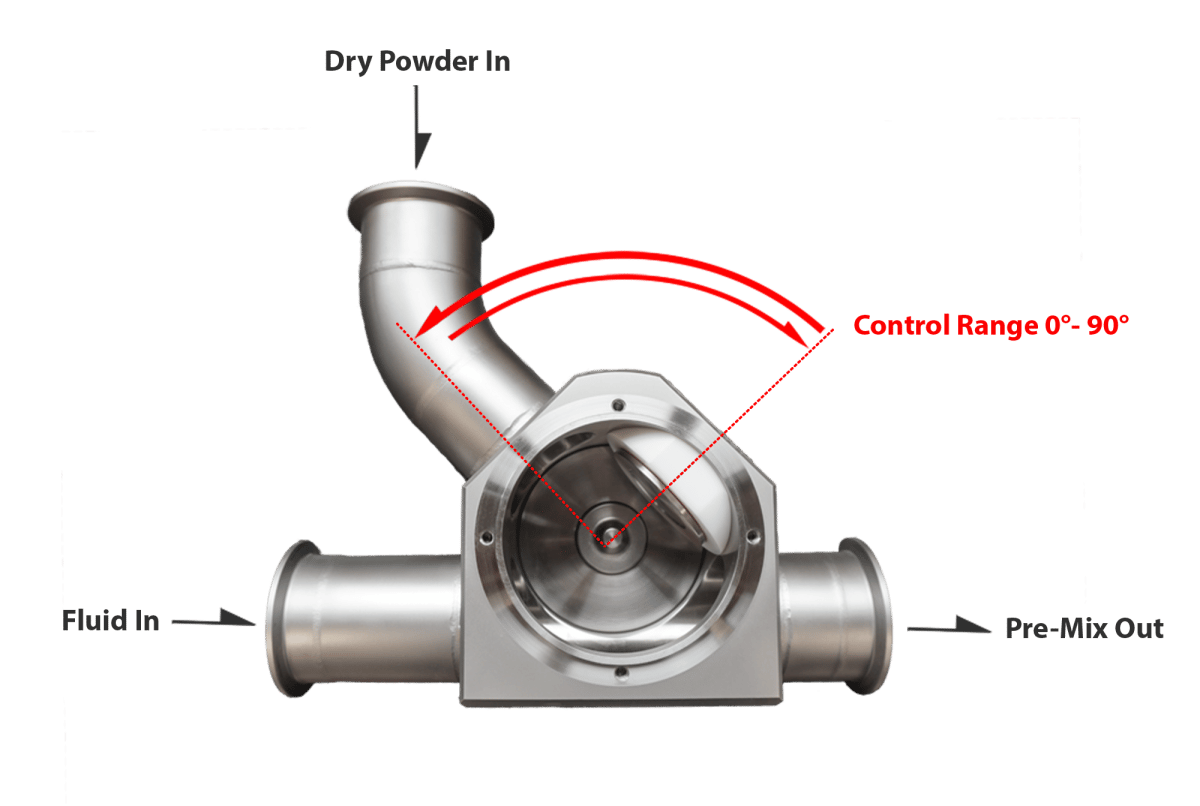

Tank Outlet Valve

Designed to take off fluids from the tank bottom, several configurations to fulfill application requirements in aseptic process.

Ideal for sanitary, high-purity, sterile or aseptic processes

Engineered for use in the most demanding process applications

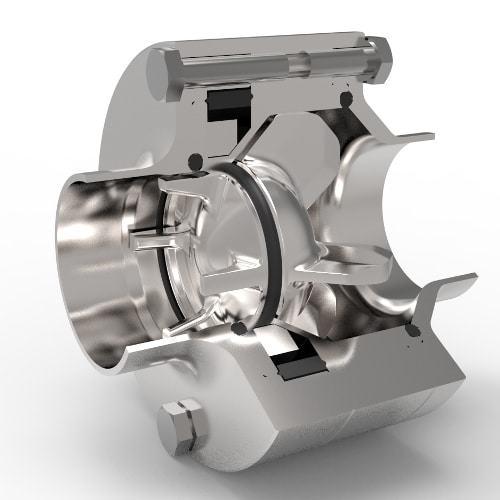

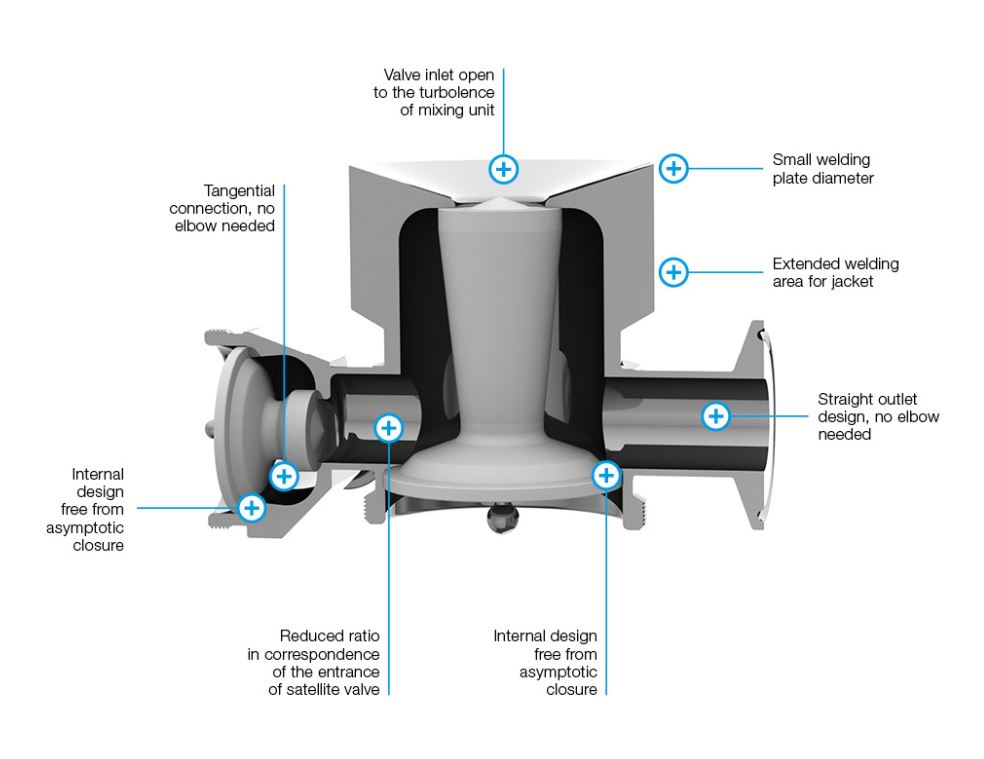

Single body seal with no entrapment areas

Self-draining

Feature that prevents over tightening of the diaphragm

Optional closed fitting satellite valve for CIP/SIP cleaning

3 available configurations: flange mounted, welded into the knuckle of the tank or machined directly into the bottom dish

USP Class VI EPDM, Silicone or PTFE diaphragms

Valve sizes: 0.5″, 1.0″, 1.5″, 2.0″, 2.5″, 3.0″, and 4.0″

Meet your clean and aseptic

process specialist

Discover our custom-made solutions and modular sanitary equipment. We join forces with our expert partners to develop, design and integrate proven solutions.