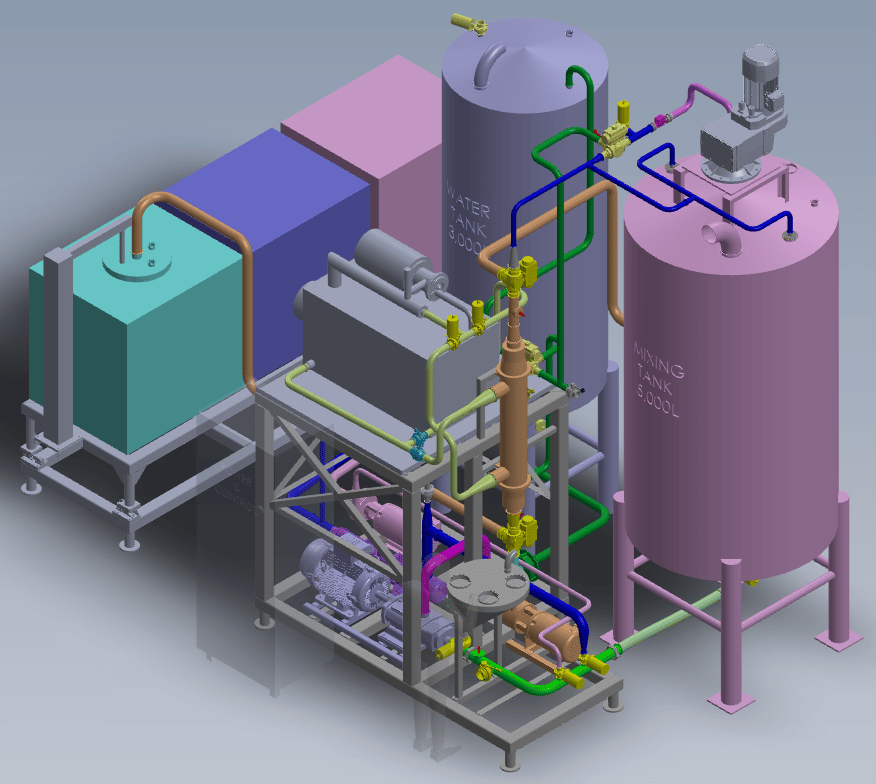

Custom-Built Process Skids

Providing engineered sanitary process systems tailored to your business needs.

Contact UsManufacture of integrated and customized process skids

Jetequip offers custom integrated process skid fabrication to create mechanical and electrical skid mounted process systems that are pre-wired and mounted on a common base to meet your specific design and process requirements.

Our team of passionate professionals with many years of experience in the sanitary industry will be dedicated to make your project successful while offering unique solutions and state-of-the-art technologies, the latter being possible with multiple partnerships we have with well-established worldwide brands.

We supply most major components including pumps, valves, mixers, instrumentation, piping, control panels and more - making Jetequip your single source solution for custom integrated process skid packages.

Jetequip has the know-how to engineer and design process skids. Starting with customer process requirements, we can develop a concept which then leads to process and instrumentation diagram (P&ID) creation, which after allows us to design, price and fabricate a turnkey process skid.

In other situations where customers have already worked on a user requirement specification package which includes all pre-engineered details, we can price and fabricate the skidded system only.

Meet your clean and aseptic

process specialist

Discover our custom-made solutions and modular sanitary equipment. We join forces with our expert partners to develop, design and integrate proven solutions.

High-end skids with contemporary standards.

Jetequip delivers premium skids with contemporary standards. Skid systems have evolved into more complex, high-quality systems. Going beyond SS 304L or 316L, such as ultra-high purity stainless (BPE), Hastelloy, AL6XN, with extremely high finish quality up to 5-10RA and electropolishing are available options. Weld procedures, qualifications, weld mapping, borescoping, elastomer and glass certifications and material documentation are all available on request. Sanitary flow components are specified to a new level of technology and quality. Sophisticated Automation; PLC automation and touch-screen HMI controls including remote process control and troubleshooting are the standard now.

- Single PO for complete mechanical/electrical skids

- Process development and design

- Component research, selection, purchasing and expediting

- Mechanical and electrical design and build

- Full 3D modelling documentation provided for every skid

- Project management for engineering, purchasing, and shop fabrication

- Automation

- FAT testing completion prior to shipment

- On-site installation and/or supervision

- System Start Up

- Training