Heat Transfer / Modified geometry tubular exchangers

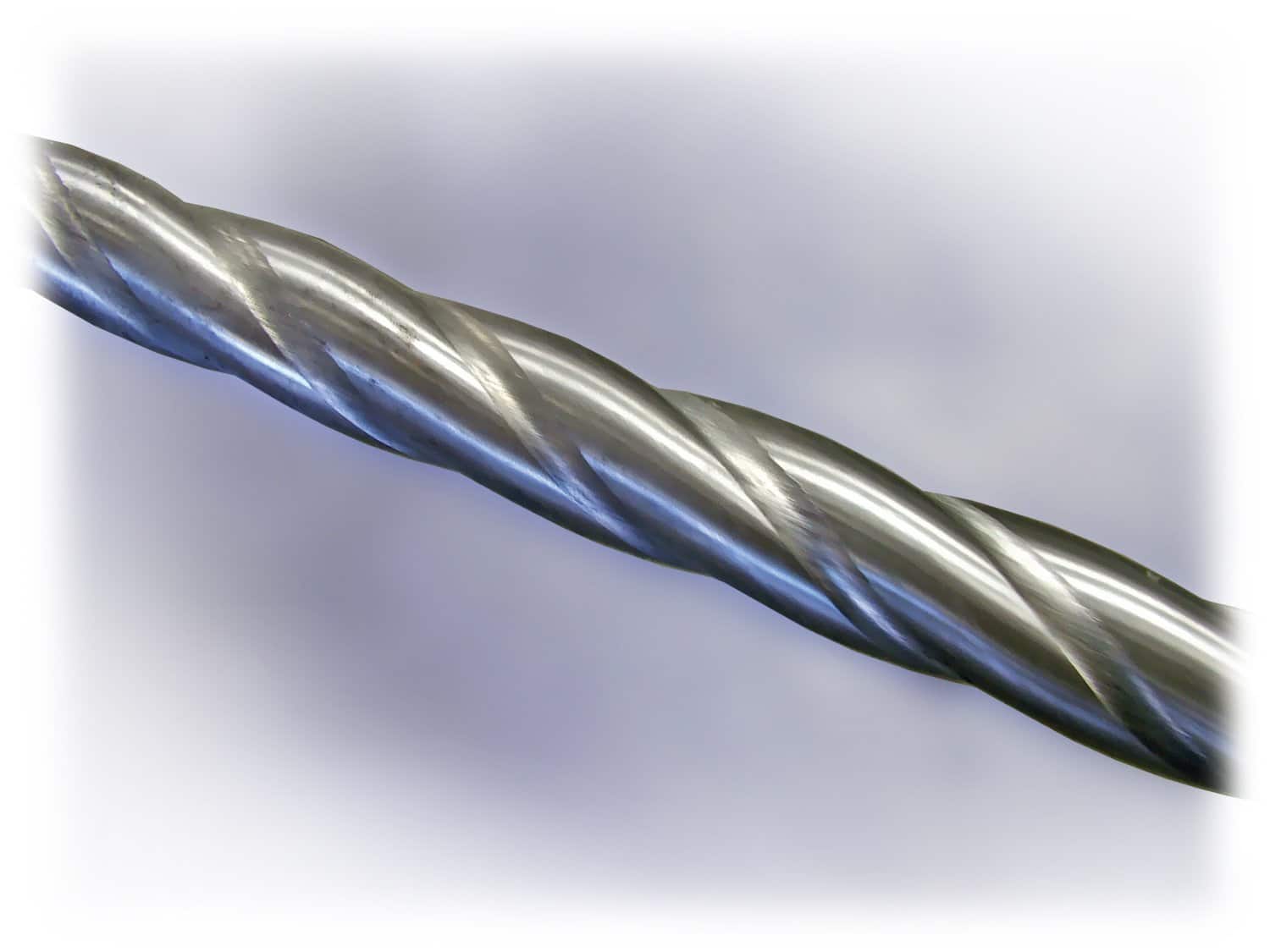

Corrugated Tube Heat Exchanger

Increase the overall heat transfer coefficient and provide an homogeneous treatment all the way through.

Tubes with modified geometry have been designed to increase the overall heat transfer coefficient and to provide a homogeneous treatment all the way through.

Indeed, in these tubes, the exchange surface is higher with respect to the volume of treated product.

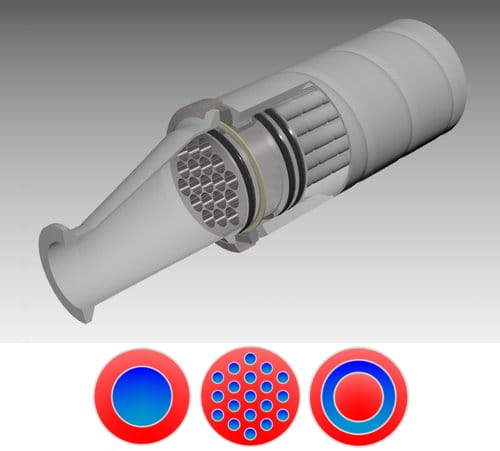

The innovative design allows the tubes to freely expand and contract independently which diminishes material fatigue and failure. Exchanger Floating Series completely eliminates failure-prone expansion bellows and rigid welds on all models.

The product flow and heating/cooling media flow are separated in concentric lengths of sanitary tubing. The unit has no moving parts, is easy to clean, easy to inspect, and easy to maintain. Tube ends, with their sanitary clamp design, can be easily removed for QC inspections and maintenance.

- Floating design

- Operational Simplicity

- Energy Efficiency: Tubes can be arranged in either direct or indirect regeneration.

- Corrugated tubes: Surfaces are shaped into turbulence-inducing, alternating parallel grooves and ridges to increase heat transfer efficiency.

- Safe: The strategically positioned elastomers eliminate the possibility of product intermixing.

- Versatility: DuoFloat, TriFloat or MultiFloat options available

Meet your clean and aseptic

process specialist

Discover our custom-made solutions and modular sanitary equipment. We join forces with our expert partners to develop, design and integrate proven solutions.