Clean in Place Solutions / CIP System

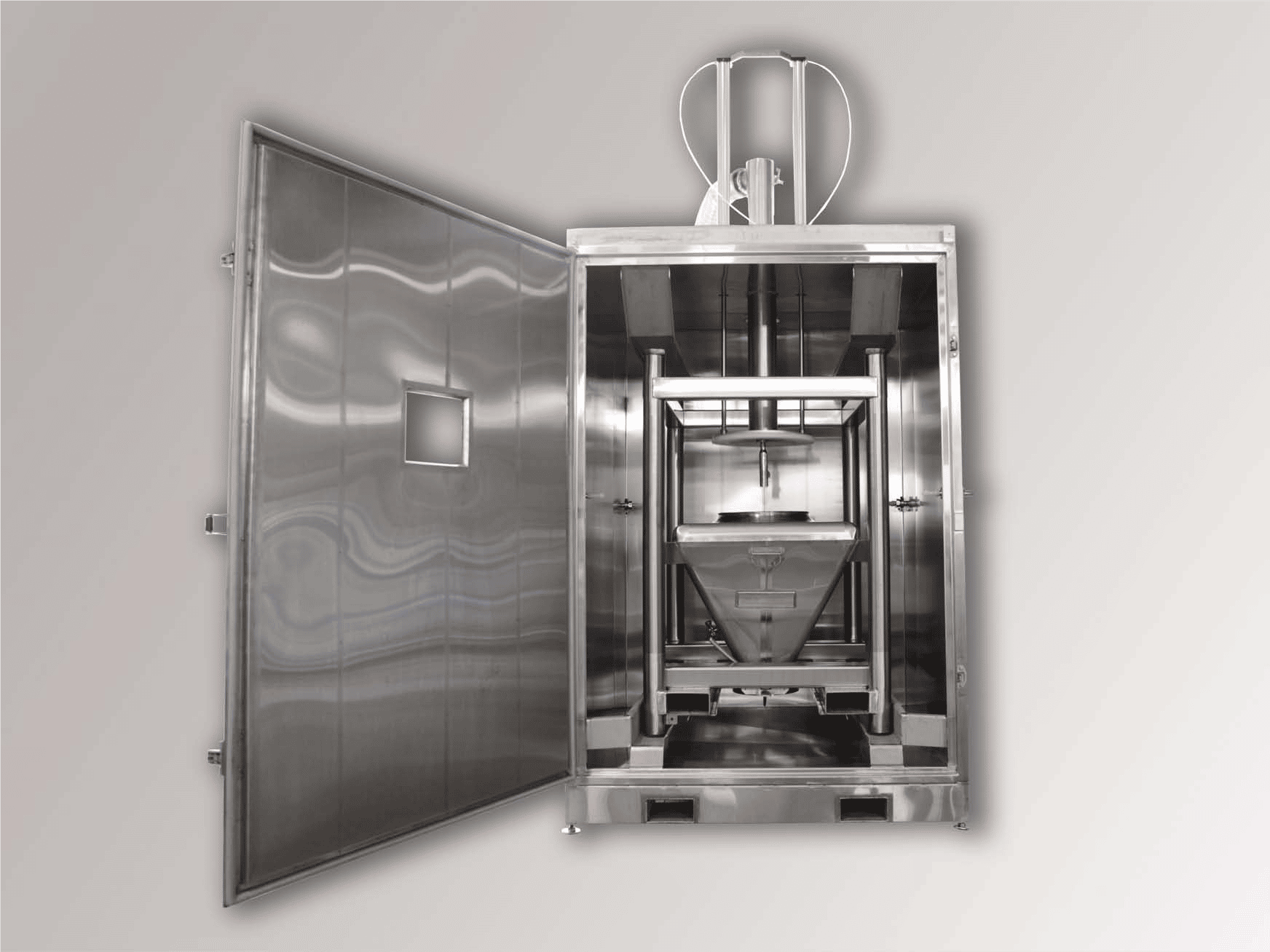

Custom CIP System

Single or multiple tank solution, full TACCT cleaning and sanitization performance and flexibility.

CIP is a method of cleaning sanitary process lines, vessels, and equipment commonly used in process plants

The process of clean-in-place (CIP) involves passing a cleaning fluid across a surface to remove product soils. Unlike manual cleaning or clean-out-of-place (COP), CIP requires no equipment removal or disassembly.

The CIP skid is the heart of CIP. The CIP skid supplies all cleaning circuits with the necessary flow, temperature, and conductivity for the correct amount of time through automated control.

Although there are many differences in design, nearly all CIP skids have common components that are vital to their functionality. These components include one or more tanks, a pump, flow meter, heat exchanger, temperature transmitter, conductivity meter, and associated valves and piping.

Jetequip offers modular, customizable, process cleaning (CIP/COP), sanitization and sterilization (SIP) equipment that are engineered, manufactured, tested and qualified in our facility. Our products have been designed with efficient performance and lean operation in mind under the TACTT* principles.

Our systems are available with various automation, integration, QA and qualification packages.

Systems built for pharmaceutical and biotech industries have stringent needs that often require special tank designs, high purity or zero dead leg valves and pumps, higher finish requirements, and full documentation. Our solutions meet the cGMP and GAMP requirements that govern the life science, pharmaceutical and medical devices industries. Upon request, the provided controls can meet CFR21 part 11 for electronic records.

- Multi-tank designs: 1, 2, 3, 4 tank designs

- Once through, single pass unit design available

- Parts washers and cleaning racks available

- Hot Air dryer option

- Vacuum dryer option – for instant drying leaving no droplet traces

- TACCT – Cleaning principles

Once the product and process parts to be cleaned are clearly defined, the time, action, chemicals, and temperature needed to provide a complete clean can be determined.

Time: The duration of time that a surface is exposed to cleaning fluid.

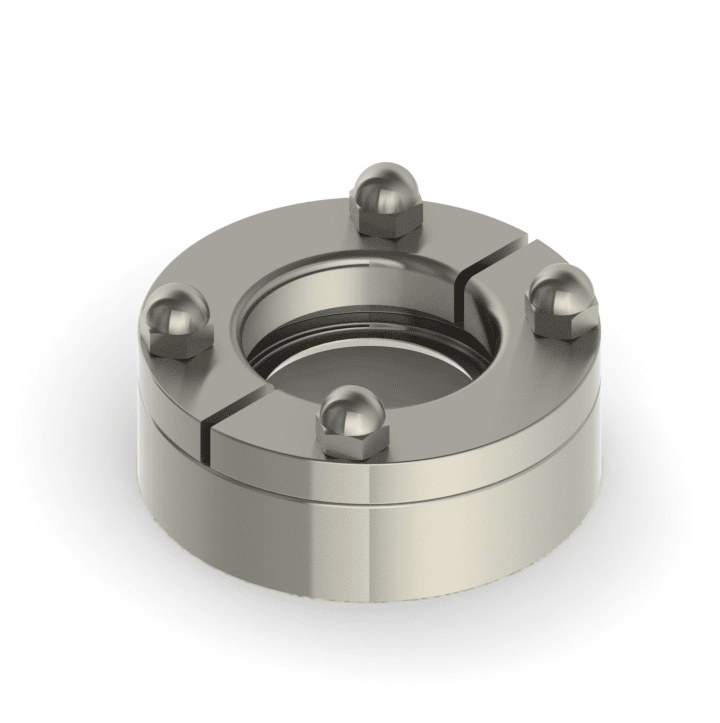

Action: The level of impingement a surface experiences during cleaning, dependent of flow velocity or spray device design.

Concentration/Conductivity: The amount of chemical per unit volume contained within the cleaning fluid. This includes caustic, acid, and sanitizer.

Temperature: The amount of heat energy within the cleaning fluid that can be transferred to a surface.

Meet your clean and aseptic

process specialist

Discover our custom-made solutions and modular sanitary equipment. We join forces with our expert partners to develop, design and integrate proven solutions.