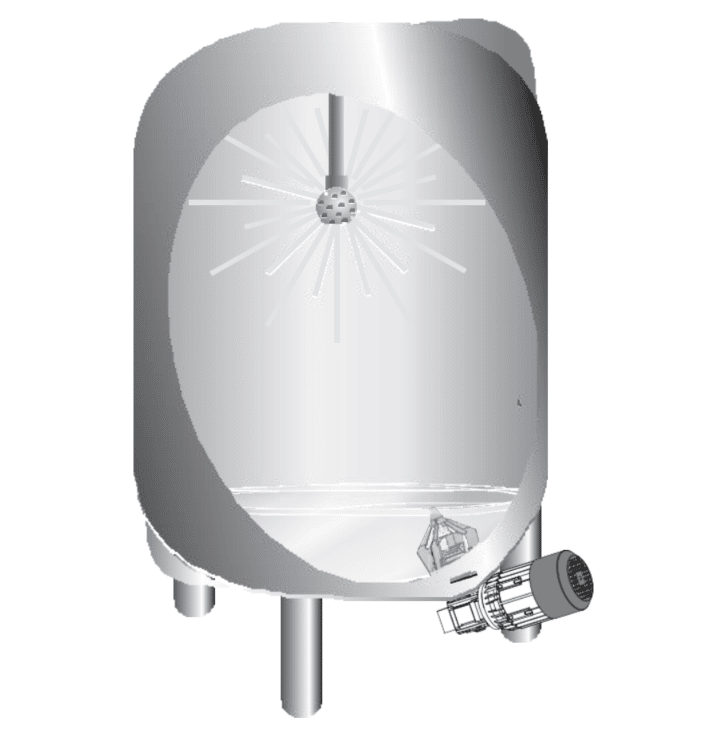

Bottom Mounted Magnetic Mixers are a highly hygienic solution for the applications of dispersion, dissolution, homogenization and mixing in the pharmaceutical, biotechnological and food-processing industries.

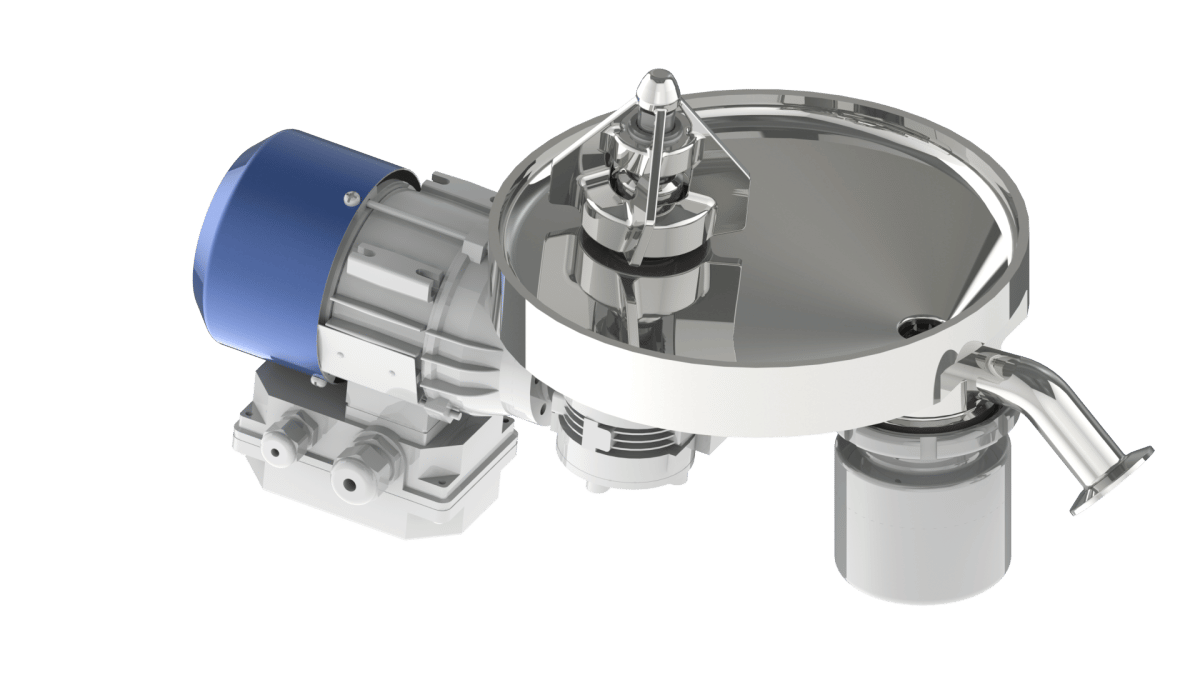

They are magnetically coupled through the bottom of the tank with no need for mechanical seals, minimizing the risk of cross-contamination.

Our range of magnetic mixers are available in three types:

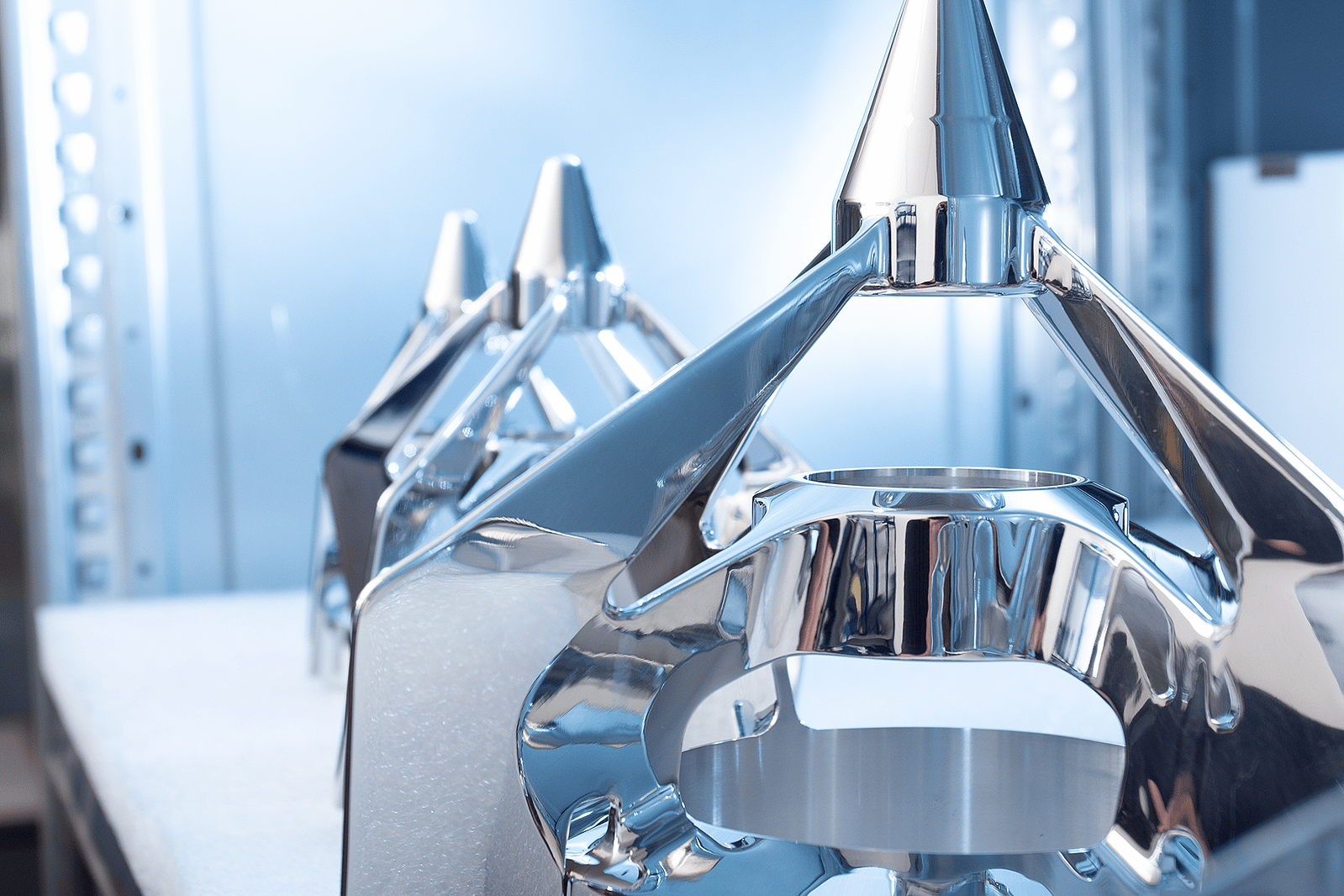

1. General mixing (Zero-G Mixer)

2. Emulsification and high shear (HS Mixer)

3. Powder and vigorous (High Power Mixer)

They are optimized for Cleaning and Sterilization In-Place (CIP/SIP) and are aseptically designed with zero dead legs with large fluid paths for high throughput of the cleaning agent.

Mixer’s durable and robust bearings ensure reliable production with minimal downtime and fast turnover time at maintenance stops. Male and female bearings can be replaced on-site in minutes.

Thanks to the floating bearing design, low volume mixing is possible as the mixer does not have to be fully covered by liquid. During vessel draining, it is possible to run the mixer ‘till the last drop without failure. Floating bearing design also minimize friction, thus particle generation, to keep your product integrity and free of contaminants.

Multiple mixing head design available, for tanks from 2 L to 30,000L

Highest level of aseptic design

Superior mixing performance

Easy maintenance

Designed for easy scale-up

Mixes until the tank is empty