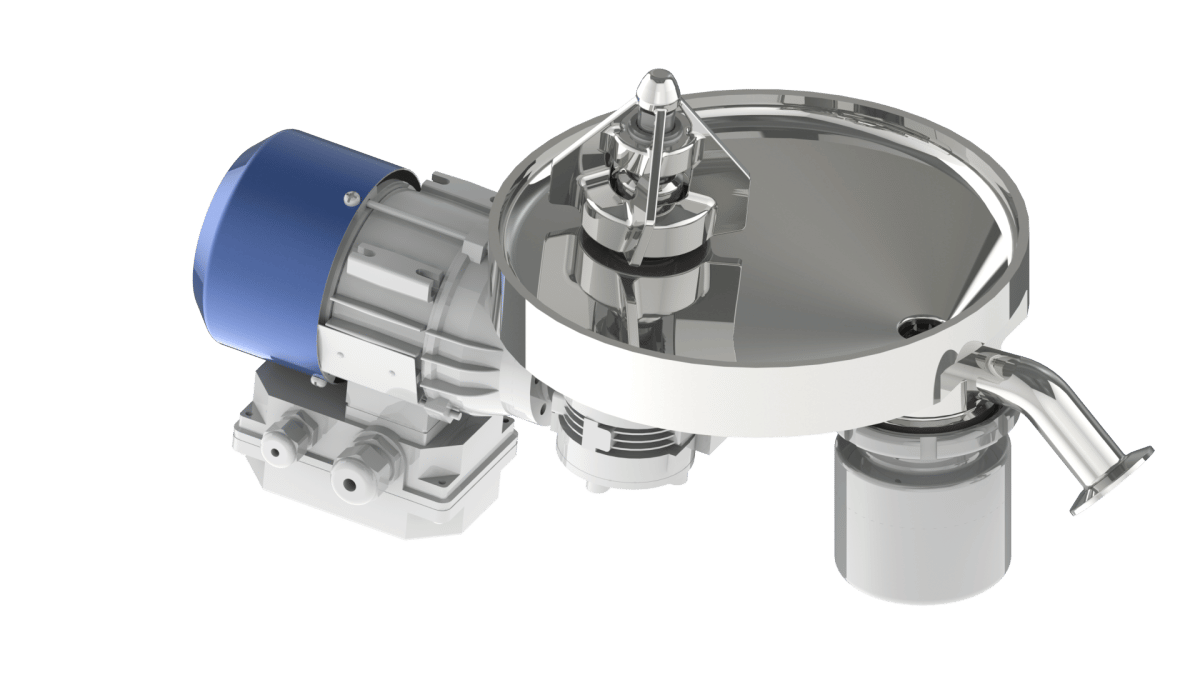

Mixers, Blenders & Agitators / In-Line mixers

Colloid Mill

High hydraulic shear for stable emulsions of immiscible liquids.

Reach sub-micron particle size

Flow rate up to 50 GPM

Quick turnaround: Save time between batches because you never have to open the mill between products

On the fly gap adjustment

CIP Clean-in-place without disassembly

Consistent particle size: Variable gap allows you to dial in the particle size you need for shelf stable emulsions

Meet your clean and aseptic

process specialist

Discover our custom-made solutions and modular sanitary equipment. We join forces with our expert partners to develop, design and integrate proven solutions.