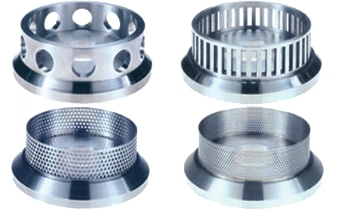

Silverson High Shear In-Line mixers are supremely efficient and rapid in operation and are capable of reducing mixing times by up to 90%. The action of any Silverson In-Line mixer can be modified with the use of rapidly interchangeable workheads. This enables any machine to mix, emulsify, homogenize, solubilize, suspend, disperse and disintegrate solids.

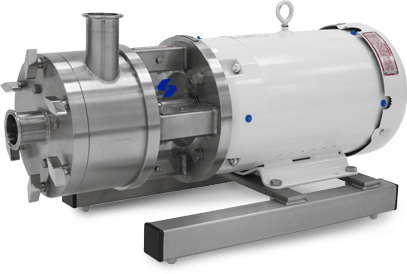

General Duty In-Line Mixers

Silverson offers a range of in-line mixers suitable for hazardous and aggressive chemical service. These robust mixers require minimal maintenance and provide some of the highest rotor tip speeds and shear rates in the industry. Self-pumping capacities from 5 to 50,000 gallons per hour.

Jacketed units are available for temperature sensitive products and construction in non-standard materials such as hastelloy, titanium and hardened steels can be offered.

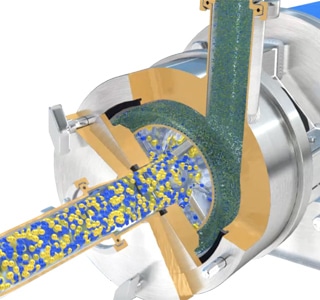

Multistage In-Line Mixer

The Multistage In-Line Mixer quadruples a number of shearing actions per revolution of the rotor, resulting in substantially faster mixing times and also increasing the number of products that can be processed in a single pass.

UHS Mixer

Silverson In-Line Ultra Sanitary mixers offer further versatility with multistage rotor/stator configurations as standard options, resulting in substantially faster mixing times by reducing the number of recirculation passes required and offering greater particle size reduction. Self-pumping capacities from 5 up to 25,000 gallons per hour.

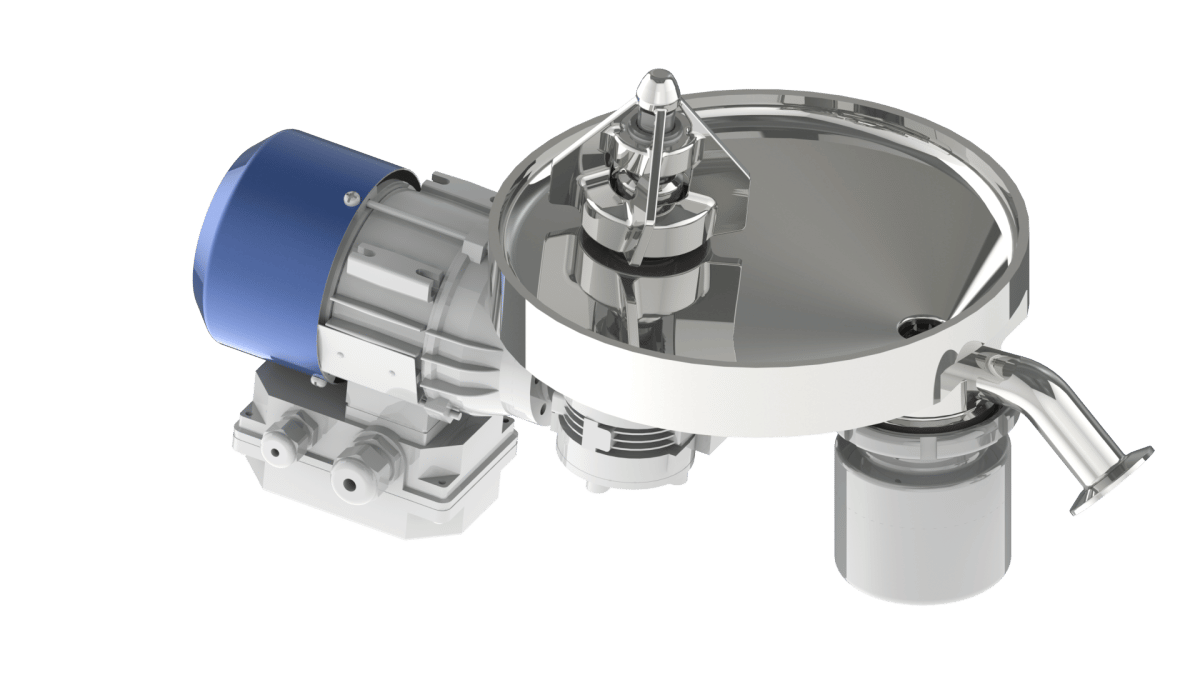

High Viscosity Mixer

Silverson’s High Viscosity (HV) In-Line Mixers offer exceptional flow rates and the ability to process higher viscosity products.

This is achieved by a unique and innovative “pumping rotor” design which substantially increases the mixer’s capacity when compared to standard in-Line mixers, eliminating the need for an additional feed pump when processing higher viscosity products in the food, pharmaceutical, cosmetics and chemical industries.

Aeration free

Self-pumping

No bypassing

Interchangeable workheads

Sanitary construction

Easy maintenance

Lower power requirements

Eliminate agglomerates and fish eyes

Creates stable emulsions and suspensions

Reduce particle size

Rapidly dissolves solids

Accelerate reactions

Self-draining tangential outlet available

Single mechanical shaft seals, easily converted to double mechanical shaft seals

CIP able